Pilbara Iron Ore

location

Australia

Deposit Style

Banded Iron Formation & Channel Iron Deposits

Client

Rio Tinto

Commodity

Iron Ore

The Client's Challenge

Rio Tinto Iron Ore currently utilises a linear programming-based scheduling model to plan and integrate their iron ore operations in Western Australia. Three primary challenges faced by the client were data preparation for scheduling, equipment modelling within the linear programming framework and visualisation of the resultant schedules.

The existing process utilised various scripts, pivot tables and complex Excel spreadsheet to prepare the scheduling inventories. This was a time-consuming process with many interfaces which could lead to data errors.

The existing models utilised by the client are complicated by many downstream decisions that are modelled to account for each possible haulage path at each mine site. Due to the size of the data set, the client required a method to clearly visualise the output of the schedule from the linear program model.

IMC's Solution

IMC Mining developed a streamlined data conversion process using the Python programming language to quickly translate a block model into the format required for scheduling and apply all relevant modifying factors. This significantly increased the reproducibility and transparency in the planning process and decreased data preparation time.

IMC utilised an inhouse developed methodology for modelling trucking hours along a system of roads within a linear programming framework that lead to significantly faster schedule solve times for the client’s model.

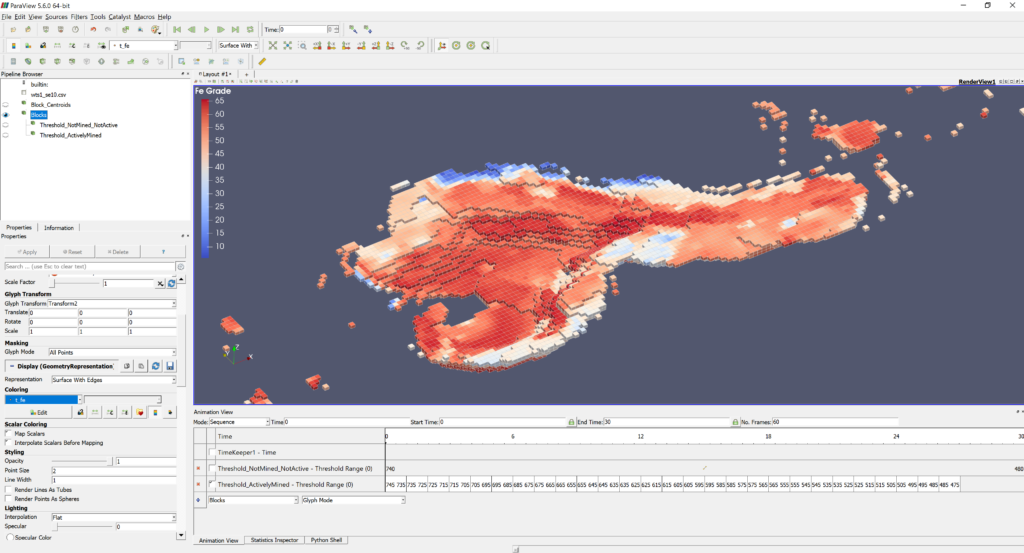

IMC also developed its own inhouse schedule visualisation solution based on Kitware Paraview that was tailored to the needs of the client. This was specifically able to simultaneously visualise the development of multiple operations in a region over time.